Manufacturing Under GMP Standards

Europe’s Largest Softgel Capsule Manufacturing Facilities Under GMP Standards

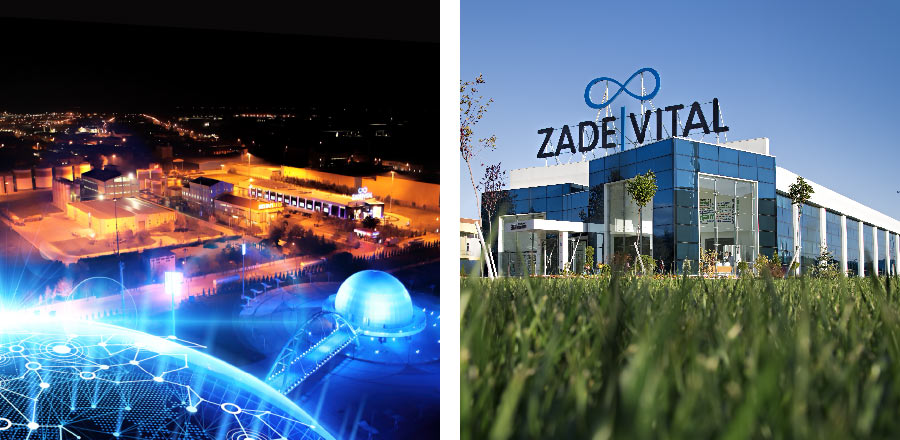

Zade Vital Drug Manufacturing Facilities built with the latest technology are the Europe’s largest high technology-based softgel capsule manufacturing facilities under GMP (Good Manufacturing Practices) standards. With an annual manufacturing capacity of 1 billion soft capsules, the plant is also capable of producing all liquid forms, semi-solid pharmaceutical forms and hard capsules.

World’s WIDEST Product Range in Cold Press Oils

The Cold Press production method, in which no chemicals are used during the production process, has been performed in Zade Vital Facilities under GMP standards for the first time in the world. Cold Press has gained great attention since last few years as it preserves the nutritional value of the oils. In the Cold Press production unit, no chemicals are used during the production process and the product’s natural nutrients and the beneficial components providing the therapeutic effect are best preserved. The most important factor of Cold Press oil production process is that heat is not applied. In this fractionation process, the oil extraction is performed independently of the heat.